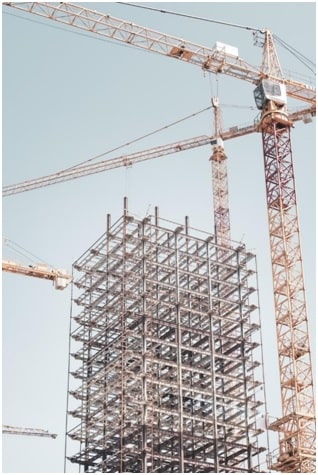

There’s no denying the prowess of cranes and how crucial they are when it comes to construction. Without cranes, lifting heavy loads will be a near-impossible task. However, as powerful as cranes are, they are also potentially dangerous. Moreover, improperly handling loads can cause serious damage.

According to the Bureau of Labor Statistics, close to 300 crane-related deaths have been reported in the US between 2011 and 2017. More than half of these deaths were caused by workers getting struck by equipment or objects, and almost a quarter of them involved the crane operator.

These statistics are quite alarming and point towards the need for improved crane safety throughout the stages of construction. Involving travel, setup, lifting, and rigging. To help crane operators and supervisors maintain safety, these tips can prove to be effective in terms of accident prevention.

1. Selecting the Proper Crane For The Job

Not all cranes are made equal and each is best suited for a unique purpose. Generally speaking, cranes can either be fixed or mobile, however, construction projects typically use fixed cranes due to the scale and complexity of these projects.

However, mobile cranes are also used in a variety of applications such as carry deck cranes are utilized for their easy setup and rotation whereas rough-terrain cranes are used on difficult terrains. In other words, there are dozens of types of cranes available, and it’s crucial to choose the appropriate crane for the task at hand.

2. Utilizing Qualified Professionals

Operating cranes is not a task for everyone as it requires proper training, certification, and periodic evaluations. Safely operating cranes is possible when trained personnel are responsible for setting up, rigging, signaling, and lifting.

Furthermore, OSHA has certain regulations requiring staff to be properly trained, certified, and evaluated before they can operate cranes on construction sites. Adhering to these regulations is also crucial to maintaining compliance.

3. Following Operator Manuals

Employing qualified professionals doesn’t mean that there’s no need for operator manuals. Different crane manufacturers have unique controls, features, and failsafe devices. Crane operators need a comprehensive understanding of every crane they’re operating.

Manuals are crucial because they provide specific and significant information regarding load capacities, operator controls, safety mechanisms, counterweights, and stabilizers, etc. Reading them properly is crucial to the safe operation of any crane.

4. Performing Regular Checks

Regular checks and inspections are also a crucial element of ensuring crane safety on construction sites. OSHA has provided specific guidelines regarding the inspection of cranes on construction sites which includes daily and periodic inspections that the operators need to perform.

Typically, crane operators use a daily inspection checklist to ensure that the crane is safe before the operation. These checks include pre-start checks, safety system checks, and engine start-up checks. Additionally, crane operators also have to perform numerous hydraulic system checks.

5. Clearing or Avoiding Obstacles

Crane travel requires a pre-planned path that should be cleared of any obstacles. Hazards that can’t be moved such as power lines or other permanent fixtures of the construction sites should be avoided, with the operator keeping a safe distance at all times.

For example, according to OSHA regulations, cranes should maintain a ten feet distance from power lines of up to 50 thousand volts. Crane travel doesn’t just require an operator but a signal person as well.

The responsibility of the signal person is to alert the operator to any potential hazards as well as warning other personnel on the construction site about the movement of the  .

.

6. Stabilizing the Crane Before Rigging

If you’re using a mobile crane, you’ll need outriggers or other stabilizing features that help ensure that the crane doesn’t tip over during the operation. Stabilizing the crane is an important task that requires following the manufacturer’s guidelines.

It’s important to determine how far should the outriggers be extended, using outrigger or crane pads underneath the outriggers. Moreover, it’s important to ensure that the outriggers aren’t placed over unsteady ground, depressions, or voids.

Crane accidents and tip-overs take place due to improper setup of the outriggers, so it’s important to properly assess the situation.

7. Rigging the Load Correctly

Proper rigging of the load is also important to prevent objects from falling and becoming a potential hazard for workers on the ground. Hitching is crucial for the proper weight distribution of the load, with basket and choker hitching being the most common configurations.

Moreover, sling angle is also crucial to rigging the load correctly. The crane operator should have a thorough understanding of weight distribution and rigging techniques to ensure a stable and safe lift.

8. Paying Attention to Load Radius and Load Limits

Load radius is one of the most important concepts to understand when it comes to safely operating the crane. Load radius determines that the further away the load is from the crane’s center, the less load it can manage without tipping over.

Similarly, load limits also require close monitoring. Modern cranes should include load indicators, load moment indicators, and rated capacity indicators. These safety devices help crane operators ensure careful and safe load handling at all times.

Bottom Line: Prioritize Safety By Investing in Crane Safety Equipment

In other words, ensuring crane safety involves a myriad of factors, and hiring qualified professionals is just one aspect of it. Construction site supervisors must arm them with the proper tools to ensure crane safety at all times.

If you’re looking for crane safety equipment for construction sites, we’ll recommend Crane Warning Systems Atlanta, the national distributor of RaycoWylie crane safety products in the US.

From ATB warning systems to Wind Speed Indicator, they offer a variety of useful products. Contact now to learn more.